- #Drawing software for grbl plotter how to#

- #Drawing software for grbl plotter drivers#

- #Drawing software for grbl plotter update#

- #Drawing software for grbl plotter software#

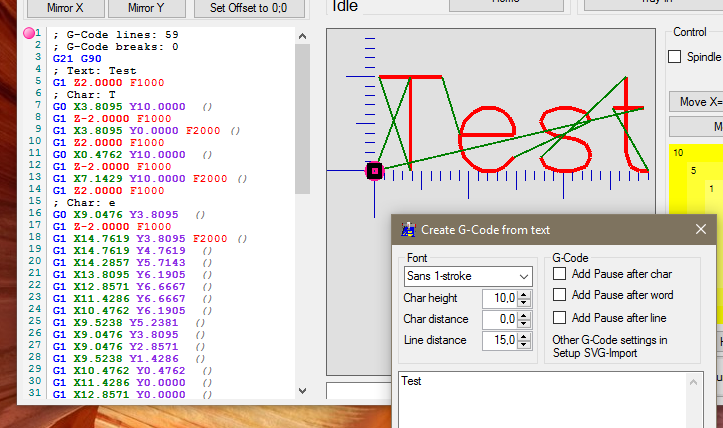

The link to part 1 of Splatspacedurham tutorial is below :-Ĭheap DIY CNC Mill Part 1 of 7 by Splatspacedurham. Also note that he glues the bushings to the sleds of the X and the Y axis, whereas I found that clamping them to the sleds, using two hole pipe clamps, was easier & better. It is basically a personal choice so decide what you would want to use in your own builds. The Linear bearings in my build give a smoother motion than the bushings he uses in his build. The inspiration to build my CNC machine came from a series of video tutorials by Splatspacedurham.ĭo note that Splatspacedurham uses bushings as glides for the X and Y axis, whereas I decided to use Linear bearings(LM10uu). In real time it took about 4 and a half minutes to draw the cat. In the video below, which is sped up quite a bit(time lapse), the machine is seen drawing a cat. The GRBL settings which were tweaked by me to control this machine, are scrolled through, at the end of the video. In this video the machine can be seen writing(Plotting) out some text. I have used the free software, InkScape, along with the Laser plugin from for generating the GCODE to draw or etch TEXT or GRAPHICS on the CNC machine. one for the X-axis and one for the Y-Axis, and then the pen on the Z-axis which was controlled by a Servo motor.įor the GUI (Graphical user interface), which streams the GCODE to the machine, I have used grblControl_0.8.4.zip from here

#Drawing software for grbl plotter how to#

Go to STEP 2, point no.2 to know how to load GRBL onto your Arduino UNO.įor my CNC machine I needed a tweaked version of GRBL by Robottini, the link to which is given in the next step below, as I needed to run two Stepper motors, i.e. Here is the link to the repositories of GRBL

#Drawing software for grbl plotter software#

The plywood was what I had lying around the house as scrap, from previous furniture projects.Įven the Stepper Motors were picked out of scrap from the streets of Mumbai, Lamington Road for Rs.150 each.They are of the TYPE 23LM series.įor the Software to control the machine I have flashed the Arduino uno with GRBL version 0.9i from Github.

#Drawing software for grbl plotter update#

UPDATE : Ebay is now non-functional in India, so the next place to get the above parts is either Amazon or One SG90 Servo has been used to lift and drop the pen onto the writing bed.Īll of the above hardware was sourced either from my local hardware store(Mumbai, Lamington Road) or from Ebay here in India.

#Drawing software for grbl plotter drivers#

To see how to build a similar machine do check out the video links which are attached at the end of this instructable.įor the electronics, I have used an Arduino Uno(clone) with Easy drivers to control the stepper motors.

(The wood used was actually from pieces of scrap that were lying around from previous furniture builds. So, even though the materials used are very inexpensive and easily available, I am happy to note that the machine is still very accurate. The idea was to put it together as quickly, and as simply as possible, but without compromising on the accuracy of the machine. This instructable is an attempt to show that a simple CNC machine can be built quite easily and quickly and that too for under US $50.

0 kommentar(er)

0 kommentar(er)